The Clark SCAM mast (Self Contained Army Mast) is a model of pneumatically-raised telescopic mast manufactured by Clark Mast Systems, down on the Isle of Wight, just off the bottom of the British mainline. The masts are used for radio communications and ariel photography.

The original customers were the various military organisations, who tended to have them mounted on the rear of vehicles or communications cabins. Alternatively the masts are packaged up for field deployment—using legs and guy-lines—by foot-based "squaddie" troops. Subsequent users have included BBC outside broadcast "radio cars", the overhead property photographic market and Police anti-hooligan camera vans. Latterly, HAM amateur radio types have tended to snap up any second-hand ex-MOD masts that become surplus—field mast kits get used in competition; and garden setups at home can avoid planning permission regulations and red tape regarding fixed permanent structures.

My personal requirement is for use on a narrowboat (a standardised type of British canal boat). Such vessels need to be able to fit within a very restrictive air-draught of 1.7 metres (5.5 ft) above the water line, in order that they reliably pass under bridges and tunnel structures while navigating the inland waterways network.

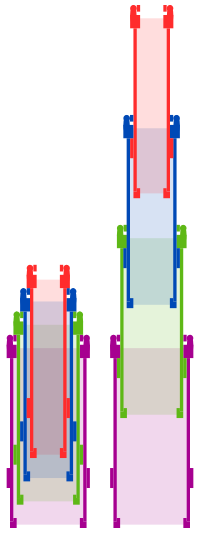

Clark (and other companies) manufactuer a bunch of masts; the military-intended SCAM version being at the more industrial end of the scale. The SCAM is composed of eight same-length (thick) aluminium tubes, slotted inside each other like a Russian doll. Despite being "military spec" and cut to high metric tolerances, the masts have surprisingly imperial-y dimensions; the following are approximations only and purely for getting the idea across:

| Tube | Outer diameter | Wall thickness | Inside gap | Height |

|---|---|---|---|---|

| 1 | 64 mm (2.5 in) | 3 mm (0.12 in) | 57 mm (1.12 in) | 1.8 m (6 ft) |

| 2 | 76 mm (3.0 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 3 | 89 mm (3.5 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 4 | 102 mm (4.0 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 5 | 114 mm (4.5 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 6 | 127 mm (5.0 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 7 | 140 mm (5.5 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

| 8 | 152 mm (6.0 in) | 3 mm (0.12 in) | 3 mm (0.12 in) | 1.8 m (6 ft) |

As a ready reckoner: when retracted, each tube extends 50 millimetres (2 in) beyond its immediate neighbour and contributes about 1.5 metres (5 ft) to the height of the structure when extended. There is roughly an 18-inch (0.4m) overlap between each pair of tubes (top and bottom) to ensure rigidity.

On the inner most seven tubes: arranged around the (outside of) the bottom end of each tube are expensive rubber seals filling the gap between it and the next tube size up. The basic premise is that as air is pumped in the internal volume formed by the tubes and their seals, the structure wants to expand like a ballon, pushing the tube sections up one-by-one. Both the inner most, and outer tubes must have sealed bottoms in order to form the pressure-tight volume. Because the number one tube is sealed at the bottom, its internal volume does not contribute to part of the pressurised area. Pressures of around 15-25 psi are used and as each section goes up thumbnuts are used to clamp the locking ring after the section inside has slide upwards.

A keying groove on the outside of each tube keeps it locked in orientation with the rest of the tubes. The entire tube assembly can be rotated as a unit whilst extended (for final antenna alignment). A freely-rotating assembly on the top of the topmost (number one) tube allows rotation without adjusting the guy-lines; the entire mast simply rotates inside it.

There are two main variants available are the SCAM 12 and the SCAM 21. The designations relate to the extended heights of 12 metres (40 ft), and 21 metres (70 ft) respectively. The only difference is the length of the core tube sections, the rest of the gubins appears to be identical. The outer most tube (number eight) has pivot plate and air inlet/outlet in the centre instead of a seal assembly and this carries the weight of the whole contraption.

Transcribed model numbers:[1]

| Model | SCAM 7 | SCAM 9 | SCAM 12 | SCAM 15 | SCAM 21 |

|---|---|---|---|---|---|

| Cat. No. | 7965 | 7050 | 7051 | 7052 | 7330 |

| Extended Height | 7.40m | 8.62m | 12.0m | 15.26m | 20.97m |

| Retracted Height | 2037mm | 2079mm | 2365mm | 2873mm | 3751mm |

| Number of Sections | 6 | 8 | 8 | 8 | 8 |

| Diameter of Top Section | 88.3mm | 63.5mm | 63.5mm | 63.5mm | 63.5mm |

| Diameter of Bottom Section | 152mm | 152mm | 152mm | 152mm | 152mm |

| Weight of Mast Unit | 66 kgs | 73 kgs | 82 kgs | 92 kgs | 120 kgs |

| Weight of Complete Kit | 142 kgs | 150 kgs | 160 kgs | 168 kgs | 197 kgs |

| Maximum Recommended Headload | 70 kgs | 40 kgs | 35 kgs | 28 kgs | 18 kgs |

| Antenna Socket Size | 40mm | 40mm | 40mm | 40mm | 40mm |

| Time to Extend Mast using Handpump with no Headload | 120 secs | 120 secs | 180 secs | 240 secs | 360 secs |

| Time to Retract Mast | 45 secs | 60 secs | 75 secs | 75 secs | 120 secs |

| Max Recommended Wind Speed Guyed | 144 km/hr | 144 km/hr | 144 km/hr | 144 km/hr | 144 km/hr |

| Picket Radius | 4.3m | 5.4m | 6.9m | 8.7m | 12m & 2.4m |

| Max. Working Air Pressure | 1.8 kg/cm2 (25lbs/□") | ||||

For the 6-foot tube sections used on the SCAM 12, the extended

height formulea appears to be approximately

(N×1m + (N+1)×18in) and

for the closed position (1m + 36in + N×2in)

where N is the number of tubes.

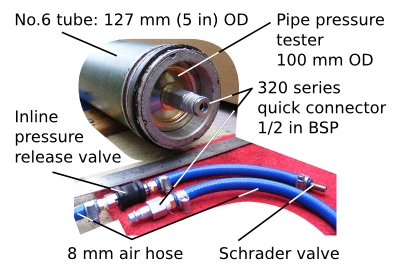

I acquired the top six sections of a SCAM 12 mast from Anchor Supplies in Nottingham, in theory giving an extension of 9.2 metres (30 ft)—about 7.5 metres (25 ft) above the boat's cabin roof. The six sections mean that the outer post tube (number six) has a 127-millimetre (5 in) external diameter. Picking this size flukily worked out quite conveniently in two ways. Firstly, the internal diameter of the bottom tube is approximately 100 millimetres, meaning that an off-the-shelf pipe pressure testing bung fits neatly (£5 from Jacksons Plumbing Centre et al). Secondly, for a quid on Ebay (well, £1, plus £15 postage...) I managed to get a 127-millimetre (5 in) vehicle bearing/mounting. The roof mounting was a bit of a random purchase and I didn't really know what I was getting other than the internal diameter, or if it would be useful in any manner.

I don't know how reliably I'll be able to use the full length, owing to a dent in my outermost tube (number six)—predating when I collected it—the number five tube tends to jam at that spot. The guy collar at the top of the mast was missing the tiny wheels that allow free rotatation along with some screws, but Anchor Supplies very usefully allowed me to raid replacements for the missing ones out of their bits box. (Spares from Anchor appear to only be available to customers who already bought a mast).

Eventually I hope to do the fixed installation in the narrowboat using small bore copper tube and proper levers hooked up to an always-on electrically backed air-supply. In the interim I have a setup with flexible tubing for testing the mast.

The 320 series connector was specifically selected as it remains rotatable under moderate pressures, and it was also the most expensive item... the beautiful inline release valve being the second most expensive. Most of the pieces then generally require hose adaptors, which bumps the cost up if purchasing new. If you're talking to a pneumatics supplier, tell them you have a "single-acting, spring return piston" (gravity brings the mast back down when gas is exhausted).

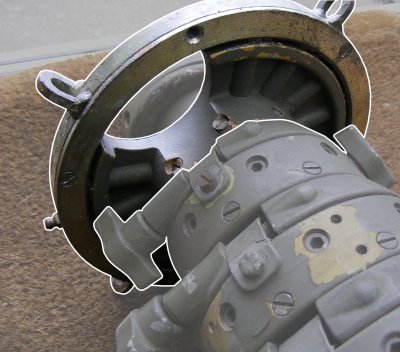

The roof mounting bearing I acquired consists of two circular metal plates with internal diameters of 127 millimetres and 134 millimetres. One plate goes flush on top of the roof and the other one against it on the inside of the roof, they are bolted together with six bolts to transmit the rotation forces to the steel structure of the roof.

The upper one of the two plates contains a nylon ring to allow the mast to rotate, so that should avoid the need for a rotator as the whole tube assembly can be rotated within the roof mount the guy line ring. Above the main ring is a further dog-leg two-part ring designed containing a rubber seal to prevent water getting to the actual roof bearing.

The roof mounting appears to have been of Hilomast origin, having now found a picture their accessories catalogue.

I've acquired a tapered rolling bearing made by Timken, although the exact mechanics of turning this into a base need to be worked out. It will need some sort of flange arrangement to keep the mast base aligned, but can take the weight, allow free rotation of the mast with the air hose passing down the centre.